Different test environments and setups call for new types of lighting with a variety of ratings to effectively illuminate each crash.

For more than 20 years Visol has been supplying high-speed photography lighting systems. Its lighting is optimized for the acquisition of images not only in the automotive safety test field, but also for international sports events and the analysis of ultra-fast projectiles in the military defense field. Backed by its experience in high-speed camera application in various segments, Visol provides consulting, structural design, custom development and production, installation, and training and maintenance to test facilities, and is recognized as the developer of the world’s first 1.2kW highpower LED lighting system. Halogen lighting and metal halide have been used for over 40 years in high-speed photography, and lead the market. Since 2000 Visol has been developing highspeed lighting systems using metal halide. However, as vehicle safety regulations became more complex and the variety of crash tests increased, so did the need for a new type of light source that would provide sufficient light capacity while being simple to control and easy to maintain. That’s why, in 2010, Visol developed the world’s first continuous-type 1,200W high-speed LED lighting, which debuted at Automotive Testing Expo Europe 2011. Design of the system took into account important feedback from customers.

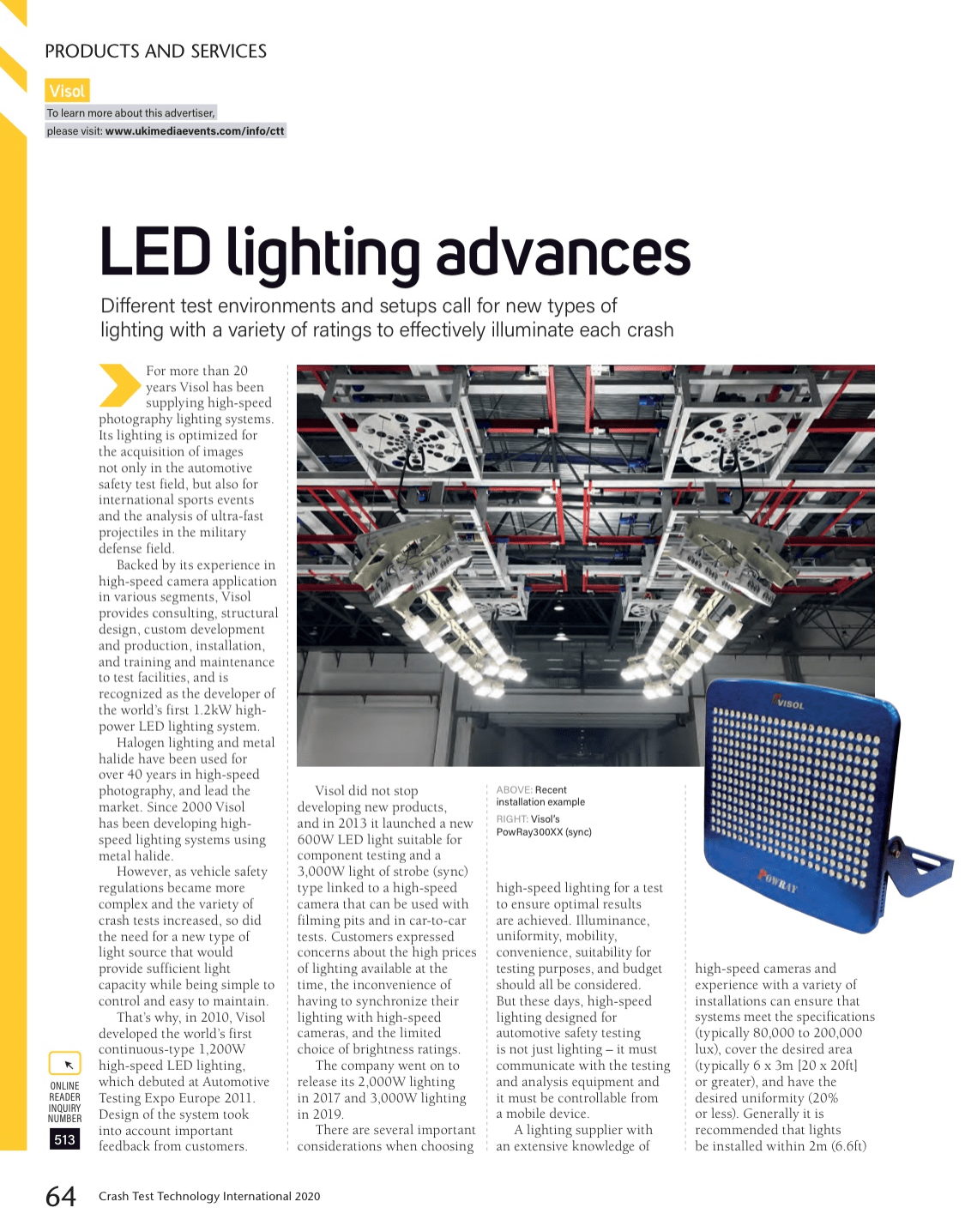

Visol did not stop developing new products, and in 2013 it launched a new 600W LED light suitable for component testing and a 3,000W light of strobe (sync) type linked to a high-speed camera that can be used with filming pits and in car-to-car tests. Customers expressed concerns about the high prices of lighting available at the time, the inconvenience of having to synchronize their lighting with high-speed cameras, and the limited choice of brightness ratings. The company went on to release its 2,000W lighting in 2017 and 3,000W lighting in 2019. There are several important considerations when choosing high-speed lighting for a test to ensure optimal results are achieved. Illuminance, uniformity, mobility, convenience, suitability for testing purposes, and budget should all be considered. But these days, high-speed lighting designed for automotive safety testing is not just lighting – it must communicate with the testing and analysis equipment and it must be controllable from a mobile device. A lighting supplier with an extensive knowledge of high-speed cameras and experience with a variety of installations can ensure that systems meet the specifications (typically 80,000 to 200,000lux), cover the desired area (typically 6 x 3m [20 x 20ft] or greater), and have the desired uniformity (20% or less). Generally it is recommended that lights be installed within 2m (6.6ft) of the static test device, 2m to 3m (6.6-9.8ft) of the sled, and 3m to 4m (9.8-13ft) of the crash test device.

You can find this newsletter in the magazine p64-65